Piezoelectric effect in mlccs multilayer ceramic chip capacitors mlccs multi layer ceramic capacitor have several advantages low equivalent series resistance esr low equivalent series inductance esl small size non polarized a disadvantage of the mlcc can be thepiezoelectric nature of the ceramic material.

Ceramic cap minimal resistance.

The multilayer ceramic capacitor and leaded film capacitor show roughly the same characteristics up to the resonance point but the self resonant frequency is higher and z in the inductive region is lower in.

In such a package there are 500 or more ceramic and metal layers.

This heating effect represents a loss in power and is equivalent to resistance in the circuit.

High voltage and high power.

The performance and cost of ceramic capacitors make them a popular option for decoupling applications.

The film capacitor and multilayer ceramic capacitor use metallic materials for their electrodes and therefore exhibit very minimal esr.

The source of capacitor loss is usually the dielectric material rather than any wire resistance as wire length in a capacitor is very minimal.

These capacitors have low equivalent series resistance esr and equivalent series inductance esl.

It is the resistance of the dielectric material itself 1.

To illustrate this point the 0402 multi layer ceramic capacitor package measures just 0 4 mm x 0 2 mm.

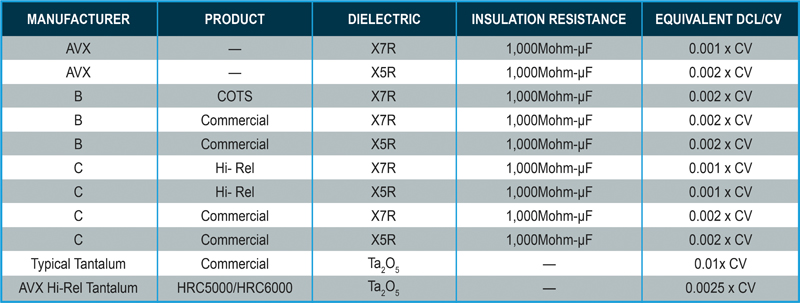

Knowing the leakage current and applied voltage the insulation.

When this composite structure is heated the electrodes tend to force the capacitor apart.

Insulation resistance ir is the extent to which the dielectric material in a capacitor resists leakage current.

While the theoretical value of a capacitor s insulation resistance is infinite since there is less.

Ir is measured by leakage current.

Around 20 ppm c and ceramic with a cte of 10 12 ppm c.

Capacitors ceramic capacitors multilayer ceramic chip capacitors.

Dielectric materials tend to react to changing electric fields by producing heat.

This tendency is made worse by ag pd being a much better conductor of heat 400 w m k than ceramic 4 5 w m k so that a thermal gradient will exist across the ceramic layer.

60 seconds while applying dc voltage without ripple between the capacitor terminals.

The minimum ceramic thickness as of 2010 is on the order of 0 5 microns.

In addition multi layer ceramic capacitors mlccs are available in a wide range of packages and capacitance values.