Loomis products piston extrusion presses are used to process powdered ceramics metals and plastics into a wide variety of profiles ranging from simple cylinders and tubes to complex honeycomb shapes.

Ceramic extrusion press.

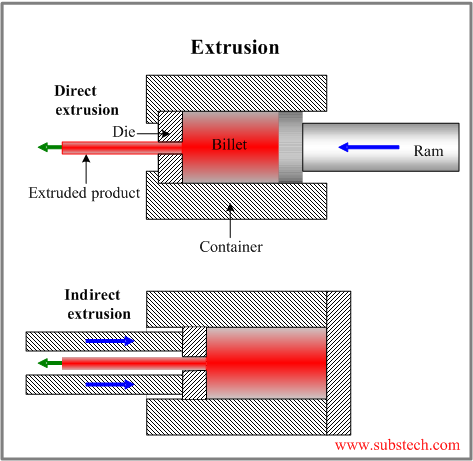

Extrusion is a process used to create objects of a fixed cross sectional profile.

Technox 500 has proved to be a very successful ceramic extrusion die material.

Technox 500 extrusion dies typically provide a 10 fold lifetime increase compared with stellite.

When properly used zircoa ceramic extrusion dies will significantly reduce machine.

The two main advantages of this process over other manufacturing processes are its ability to create very complex cross sections and to work materials that are brittle because the material only encounters compressive and shear stresses.

Pottery techniques include the potter s wheel slipcasting and many others.

These are high temperature low expansion materials allowing them to withstand fluctuations in extreme temperatures inside your engine.

Ceramic forming techniques are ways of forming ceramics which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts.

Extrusion picture supplied by barwell limited this forming process consists of forcing a plastic mix of a ceramic powder through a constricting die to produce elongated shapes that have a constant cross section.

To begin the extrusion process high quality raw materials are blended to create a homogenous mixture.

Technox 500 is strong tough and unlike conventional materials not susceptible to creep at extrusion temperatures maintaining product size for the life of the die.

Specialized ceramic extrusion equipment is designed and built by diamond america for a wide range of ceramic products.

Zirconia ceramic extrusion dies from zircoa are frequently used with a direct press in which the billet moves through the die.

Extrusion press for ceramic extrusion press for ceramic suppliers directory find variety extrusion press for ceramic suppliers manufacturers companies from around the world at aluminium extrusion press extrusion press aluminium extrusion press for sale punching machines.

To learn more visit.

Next liquid is added to the raw material mixture and poured into a conical hopper.

Our dies are equally successful in an indirect press in which the die moves through the billet.