Rheological properties and debinding effects on the sintered part article in ceramics international 39 3 2665 2674 april.

Ceramic injection molding temperature for ysz.

Micro powder injection molding pim of metals or ceramics is an alternative to fabricate structures of these materials in large series especially in the micron range.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment.

Yttria stabilized zirconia ytzp is the strongest ceramic material we offer.

The effects of powder loading and temperature c on the rheological behavior of the ysz were investigated by using rosand rh2000 capillary rheometer.

Ytzp exhibits a trait called transformation toughening which allows it to resist crack propagation.

First is pyrolysis to remove the binder followed by sintering in a high temperature kiln to form a fully dense ceramic component.

The results showed all the feedstock achieved desirable injection.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components.

Ceramic injection molding cim overcomes this issue by forming net shape parts in the tool.

Export carton supply ability.

This method is well established in replication by injection molding and metal injection molding mim or ceramic injection molding cim.

Yttria stabilized zirconia formed by micro ceramic injection molding.

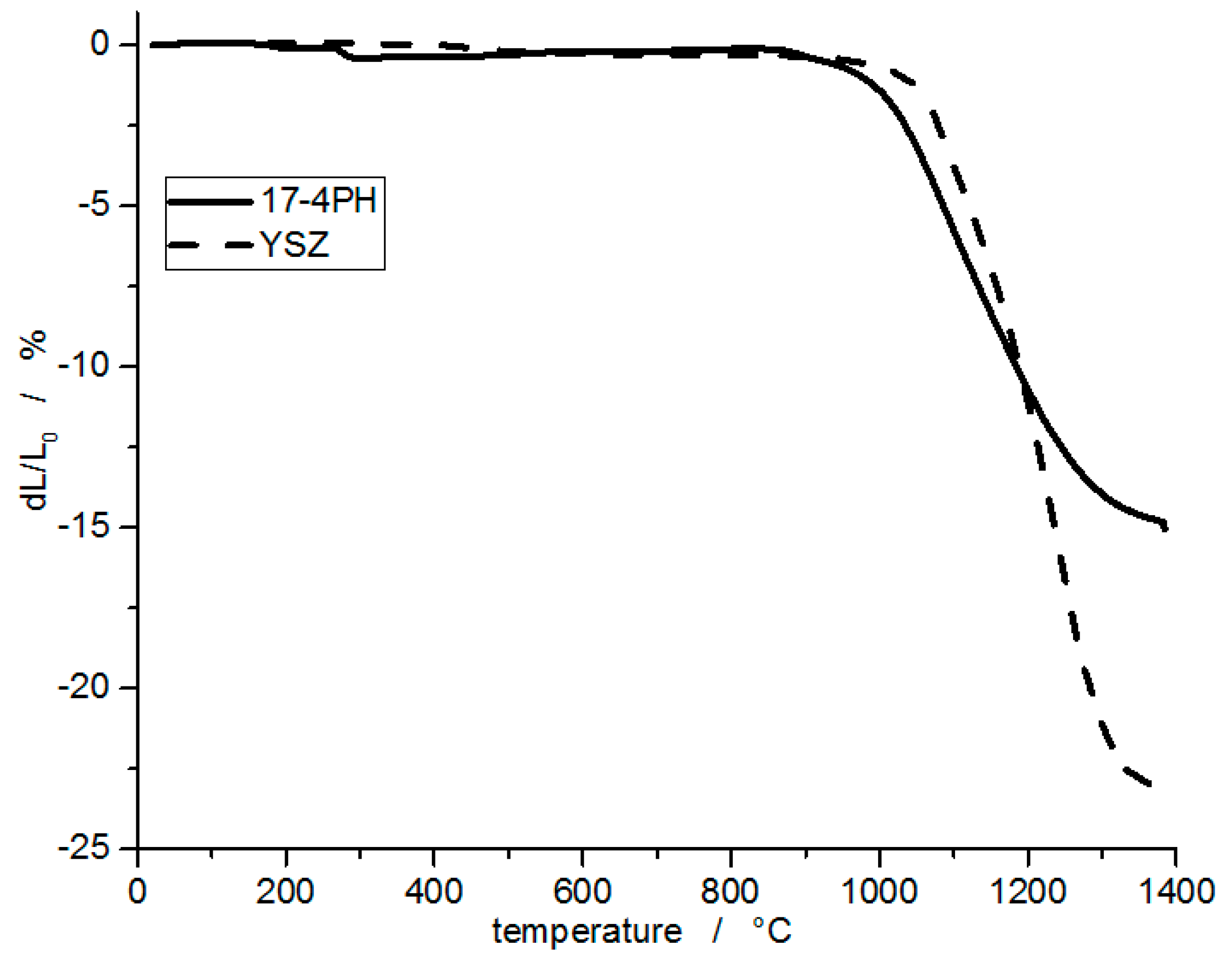

During sintering the component shrinks uniformly by as much as 20 while retaining the complex shape.

3 1 2 2 micro powder molding.

The single sofc which consisted of nio ysz anode supports a thin ysz electrolyte film a lsm ysz cathode and a lsc current collection layer could deliver a maximum power density of 450 mw cm 2 at 0 6 v when operating at the temperature of 810 c.

This material offers the highest flexural strength of all zirconia based materials.

Ytzp is a purely tetragonal phase fine grain material.

The cim process gives production engineers and product designers more versatility in the use of ceramics as an alternative material with higher productivity lower manufacturing cost s and improved product performance.

Ceramic injection molding was also applied to manufacture planar anode supported sofcs of.

Y psz yttria stabilized zro2 zirconia ceramic tube.

500 000 sets month y psz yttria stabilized zro2 zirconia ceramic tube the specification of ceramic tube raw material zirconium oxide aluminum oxide silicon nitride silicon carbide forming methods dry pressing hot pressing iso pressing ceramic injection molding extrusion typical.

The ceramic mixtures showed.

Shear rate for the feedstocks at the injection temperature 1801c.