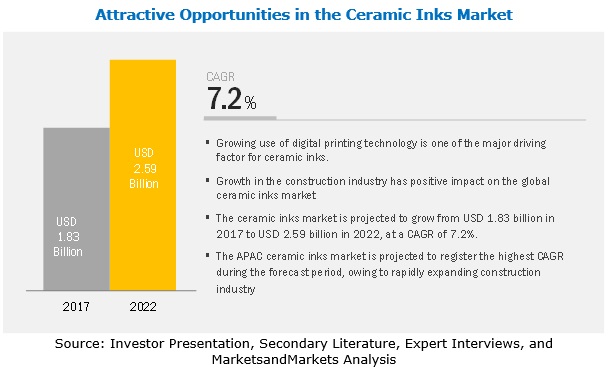

Ceramic inks market research report by type decorative inks and functional inks by formulation solvent based and water based by technology by application by industry global forecast to.

Ceramic ink formulation.

Innovative ceramic corp designs and manufactures a large variety of high temperature ceramic inks to meet virtually any custom application simply provide us your project details such as at what point in the process the product will be marked for example green state wet dried before or after glaze bisque after fire etc.

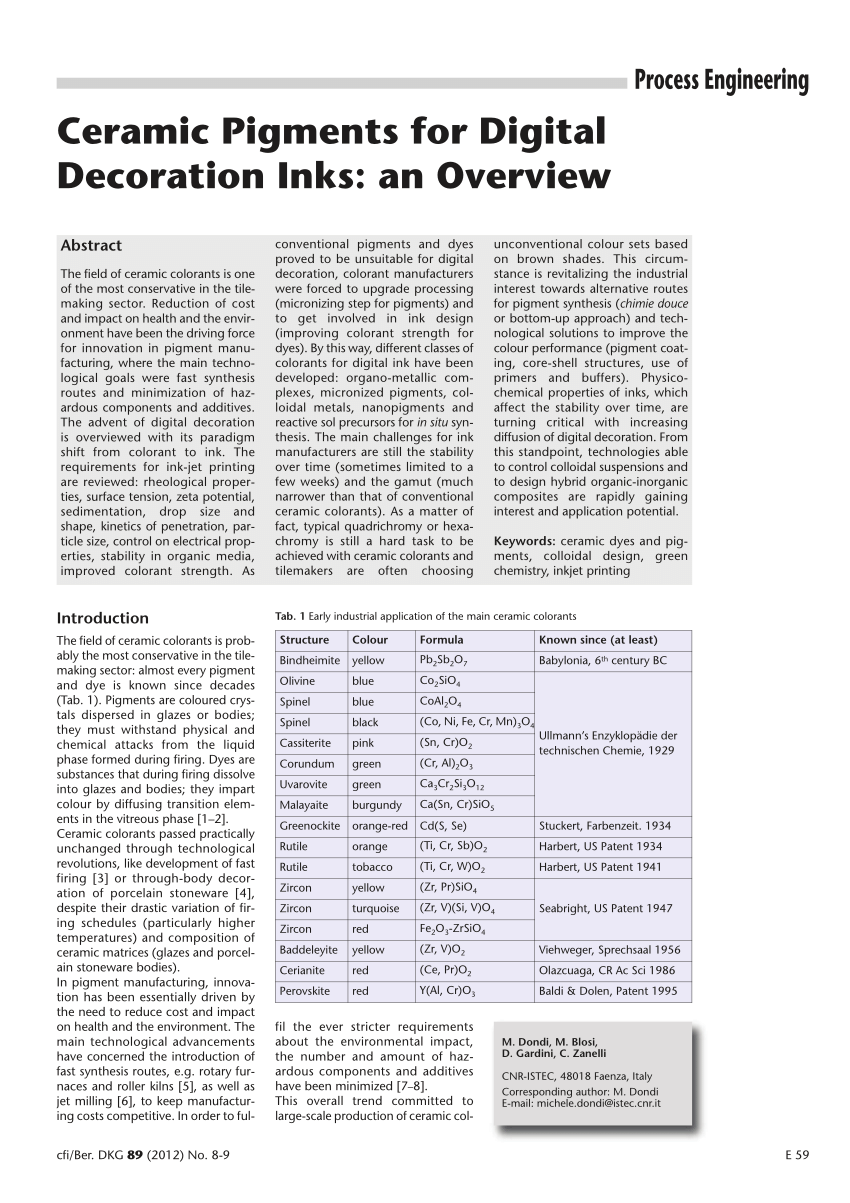

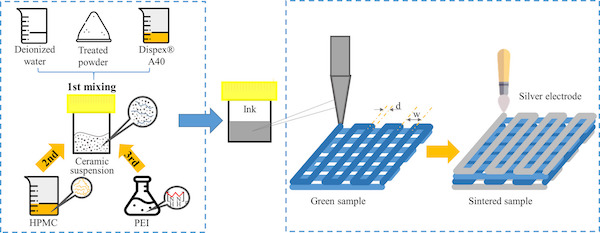

The ink making process has been described elsewhere.

The ink composition is shown in table 4 and the ink properties in table 1.

Practically the ink reversibly gels upon extended standing thus preventing sedimentation entirely.

The ceramic ink having a viscosity and surface tension within the printing range was prepared.

Marabu specializes in organic inks for glass a highly effective and energy efficient alternative to ceramic enamels.

Inks substrate activators can be added to ink producing superior adhesion to both glass and ceramic in addition desirable properties such as scratch resistance and wear resistance can be incorporated into the formulation.

An ink jet recording method includes ejecting an ultraviolet ray curable ink of which a viscosity at 28 c.

How much handling and how soon after marking firing.

Is 8 mpa s or more from a head to a recording medium and curing the ultraviolet ray curable ink attached to the recording medium wherein in the ejecting of the ultraviolet ray curable ink the ultraviolet ray curable ink is.

Our ink systems score highly on adhesion and come in a variety of colours and special effects plus they are scratch resistant dishwasher safe and free of heavy metals.

Formulation of the aqueous yellow ceramic ink the aqueous yellow ceramic ink was formulated by mixing distilled water and 15 vol of the yellow ceramic pigment.

A solvent based ink formulation for inkjet printing particularly on plastics and non porous surfaces including 1 40 by weight of a ketone solvent 10 90 by weight of a mixture of cosolvents 0 1 10 by weight of a co polymer binder 0 1 10 by weight of dispersants wetting agents and 0 1 10 of plasticizers to give a formulation having flash point higher than 60 degree.

The dispersion stability of the aqueous ceramic ink was characterized upon the addition of sodium dodecyl sulfate sds.