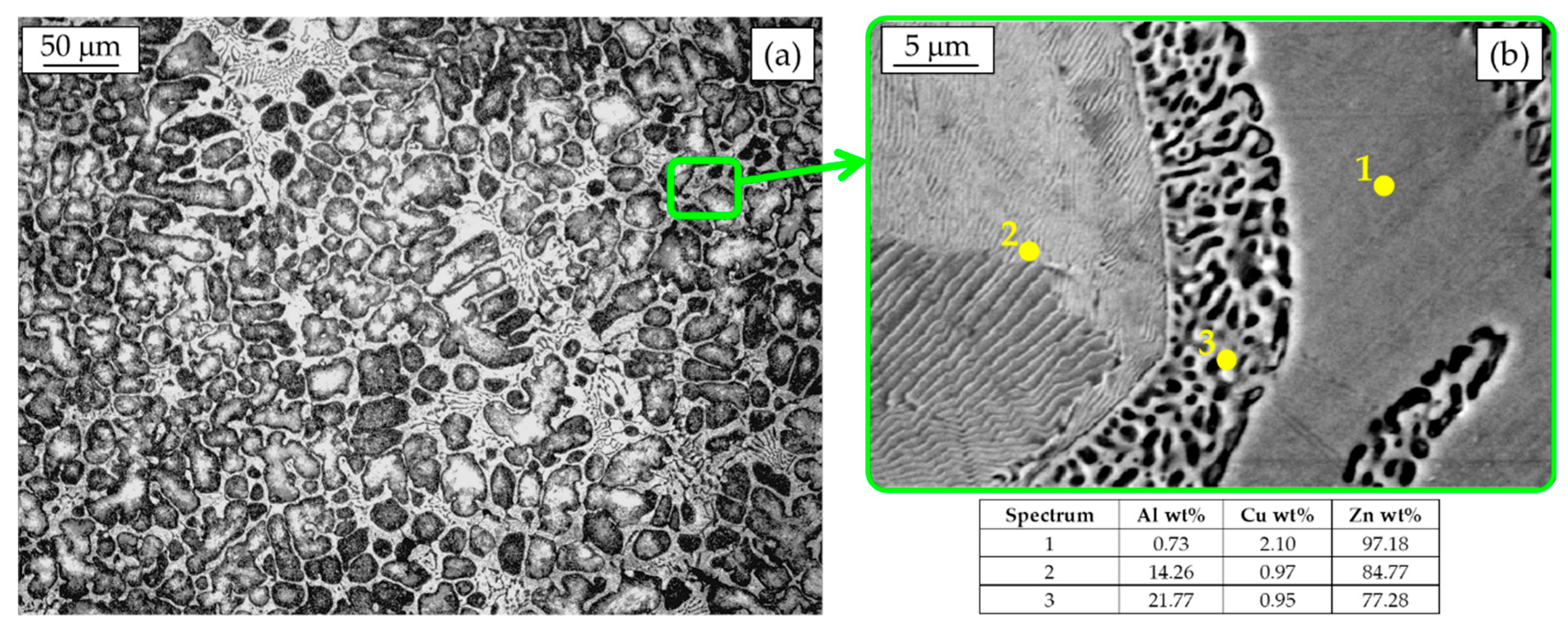

Open celled zinc oxide ceramic foams were prepared by the polymer sponge replication schwartzwalder technique from aqueous zno dispersions with sb 2 o 3 and bi 2 o 3 as sintering additives and mechanically stable zno foams with an average porosity of 93 6 were obtained.

Ceramic oxide microstructure.

The common engineering ceramic materials can be identified as aluminium oxide alumina silicon carbide silicon nitride sialon and zirconia.

Ho2o3 transparent ceramics were fabricated by vacuum pre sintering combined with hot isostatic pressing hip post treatment at relatively low tempera.

Their microstructure consists of zno grains with a bi containing grain boundary phase together with a zn sb o secondary.

Haber richard a chair.

Schäfer preparation and microstructural analysis of high performance ceramics asm handbook volume 9.

Niesz dale e internal member.

Matthewson michael j internal member.

These fibers that mostly consist of alumina al 2 o 3 and alumina silica al 2 o 3 sio 2 mixtures due to their high melting points are generally used for high temperature applications.

Title the effect of microstructure in aluminum oxide ceramics on acoustic loss mechanisms name bottiglieri stephen author.

Brennan raymond e outside member.